Category: General

-

Solved: 2014 Mazda 3 Intermittent Liftgate (trunk) Latch, Won’t Open

TL;DR: Software locked it out because front passenger side door latch detects a nonexistent key in its nonexistent keyhole. It ultimately wasn’t, but could have been, dependent on which hand you used to open it! Before I begin – and before anyone pictures me with cape and golden locks blowing in a heroic breeze –…

-

Got a health survey call from BRFSS?

TL;DR: Noping out of a probably-not-a-scam scientific study that should benefit everyone, with the ongoing realization that I can’t currently trust the fucking CDC not to do me or my family harm instead of good in the current administration. Takeaways: I try not to get into overtly political topics here, but there’s no dancing around…

-

Clippy, just trying to be helpful!

Louis Rossmann, my spirit animal from the alternate reality where I don’t have a day job and kids, is again speaking some truths. He makes a great argument that we should be pining nostalgic for Clippy, the dancing paperclip everyone of a certain vintage hated for being naively helpful, as opposed to hating our industry…

-

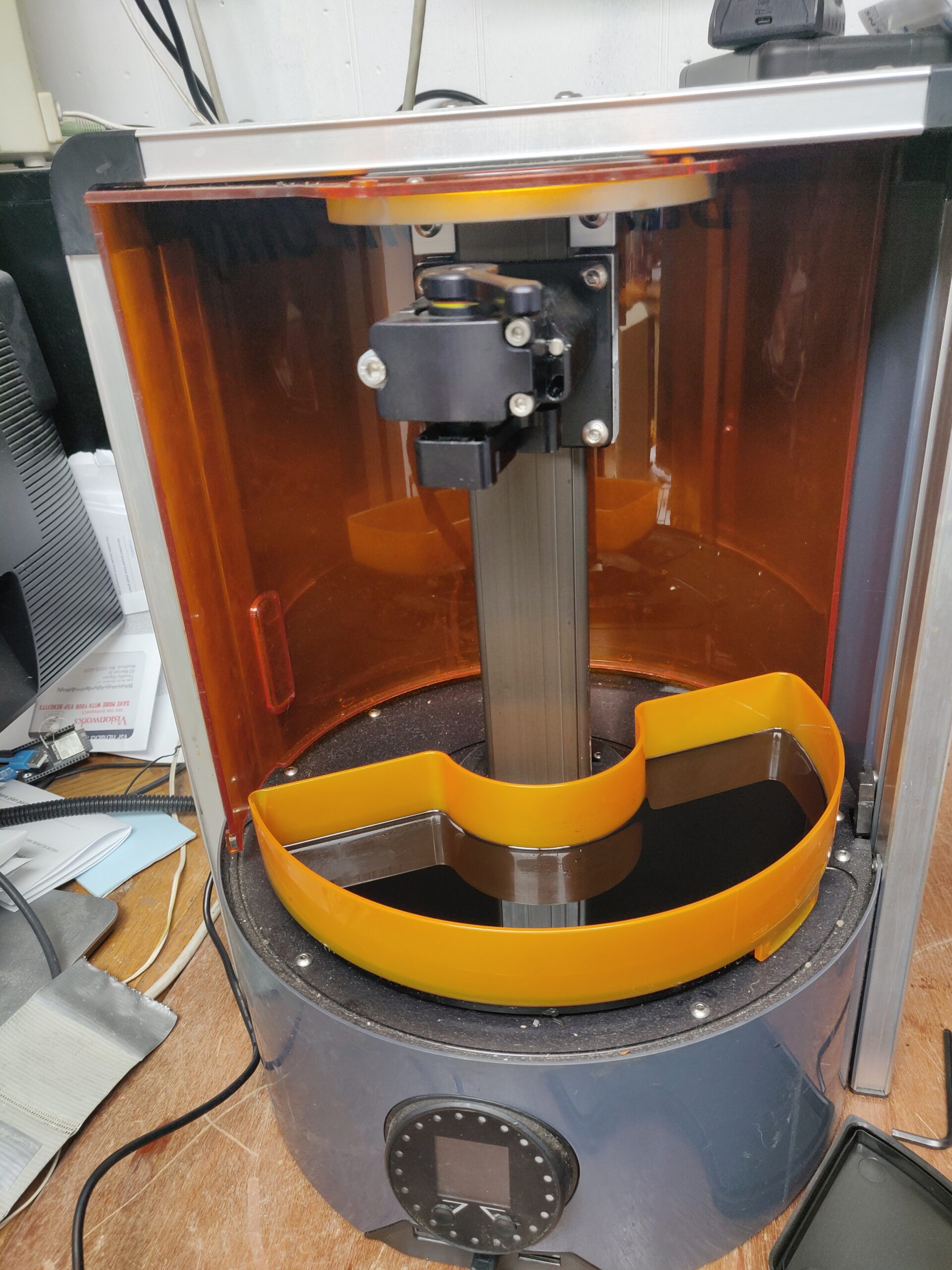

Autodesk Ember SLA (Resin) 3D Printer – Findings, Document Dump and new Slicer!

Or: Tim reverse-engineers an open-source product to reconstruct the open-source materials! Long story short, I picked up this Autodesk “open-source” (words I thought I would never hear together) stereolithography printer at a local freecycle event. I thought it was a vacuum cleaner until I saw the Autodesk name on the back label. On realizing what…

-

Kalmbach Media / Discover Magazine Subscription Scam

Hello friends from the search engines! If you’re reading this, you’re not the only one to receive one. With apologies in advance for turning this blog into an archive of my snail-mail, here is an “invoice” I got the other day, for a magazine I used to have a gift subscription to years-and-years ago. As…

-

KoolStone Rock Tumbler Replacement Belt sourcing

A very quick note to my future self: AFAICT the KoolStone (iKoolStone?) belts are plain rubber O-rings, which come in standardized size numbers. For the KoolStone (C1? 2.5lb capacity) rock tumbler, it is size 231 (approximately 2-5/8″ ID, 2-7/8″ OD, 1/8″ width). Durometer unknown, but 50A durometer seems to be working well. These can be…

-

Pandemic Project: Aquascaping with Insulating Foam & Found Objects

“The pandemic is over!”, says the world, as I sit here cooped up in a household full of COVID and no childcare :p Anyway, a bit late writing this up, but when the actual COVID lockdowns were going strong and everyone needed hobbies, I decided to put together a nice fishtank aquascape using mostly stuff…

-

Not enough ass in your pants?

Growing up, when someone was attempting a job that was clearly too big for them, my uncle would say: “You don’t have enough ass in your pants for that!” What this expression meant of course was that all the strength, gumption or determination in the world were irrelevant, and the task at hand just required…

-

MAPFRE Data Breach, or, “What’s a MAPFRE and why do they have my information?”

So, I had this brilliant idea for a legitimate passive income opportunity: Start a company with an online presence and terrible information security. Buy personal information in bulk, store copies of it on our servers, then sit back as eeevil hackers steal it. Repeatedly. Each time it happens, offer the affected customers 12 months of…

-

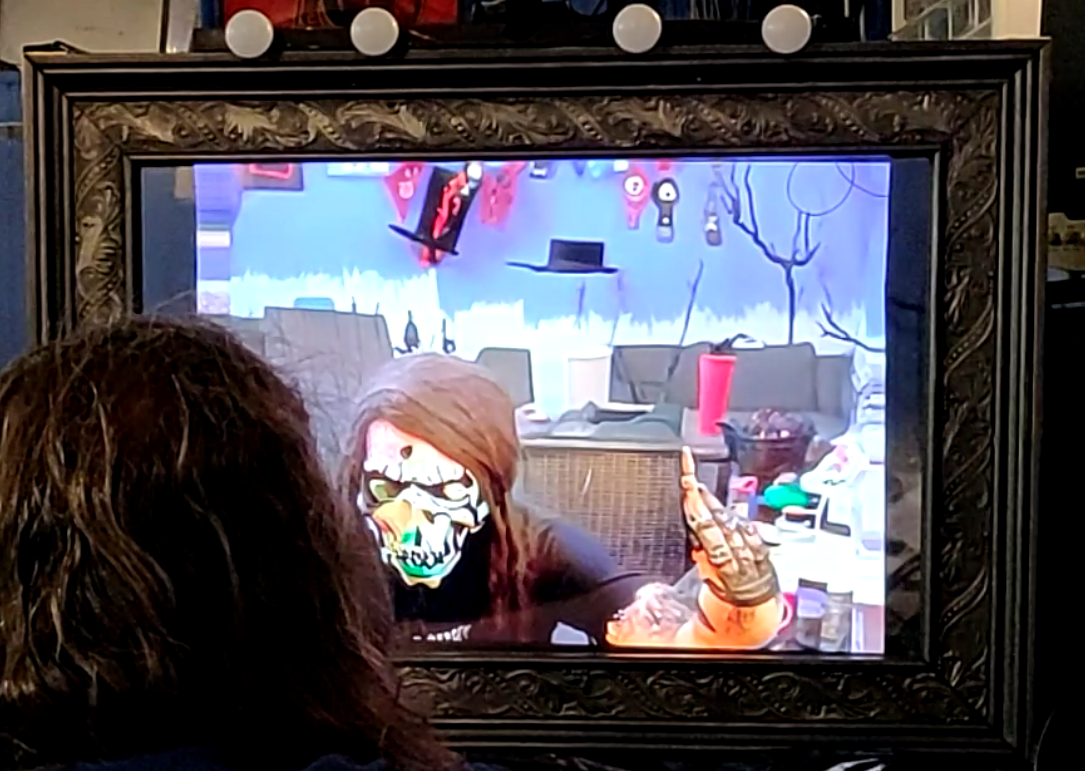

Spookifying Haunted Mirror build using Stable Diffusion

For this Halloween, I built this haunted mirror display for the porch that turns any trick-or-treaters extra spooky. Using the voodoo power of AI, those who gaze into the mirror will be treated to a visage of their best Halloween self. See below for code and build tips if you’re interested in making your own!…

-

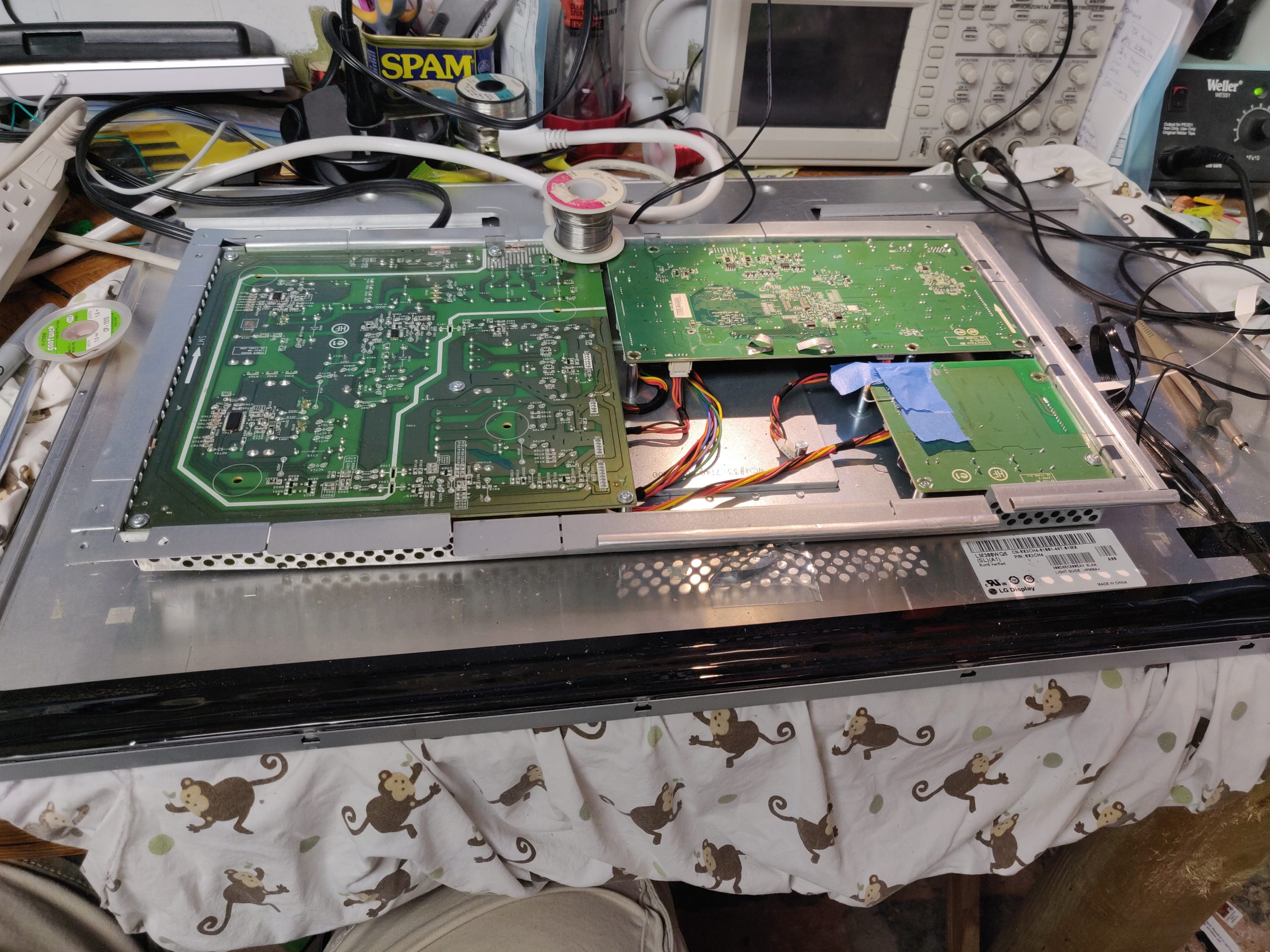

Fixing Dell Ultrasharp (U3014/U3014T) Monitor Not Working (Now with Firmware!)

So, I found this lovely behemoth in my work’s e-waste pile and yanked it out, figuring on harvesting a nice big diffuser and backlight for a different project. But a quick search on the partnumber showed this thing is pretty impressively specced, and maybe I’d rather have a go at getting it running again instead.…

-

Solved: YouTube Watch Later ‘Remove Watched’ missing 2021

TL;DR: Watch one of the first 10 videos in your “Watch Later” list and see if it magically reappears. Doing a web search for this problem reveals it has been an issue for some time, but possibly for varying reasons in the past. The above is working for me on Web + native clients as…

-

Sticky Nano Heater, a small fishtank heater that stays dry

While procrastinating on my current year+ long “couple long weekends” project, in which I’ve clearly bitten off more than a post-kids me has time to chew, I set my sights on a stupid-simple project I could actually complete :-) This is an adhesive stick-on fish tank heater for nano aquariums. The thin PCB trace heater…

-

Potential Safety Flaw in Home Depot HDX brand wire shelving units

Asbestos undergarments? Check. Lawyer-proof socks? Check. Here we go. I got a small safety lesson over the weekend I wanted to share. Officially, it’s about an extremely common design of wire-rack shelving units, but the real safety lesson is to double-check the workmanship of load-bearing products with a critical eye, because the manufacturer may not…

-

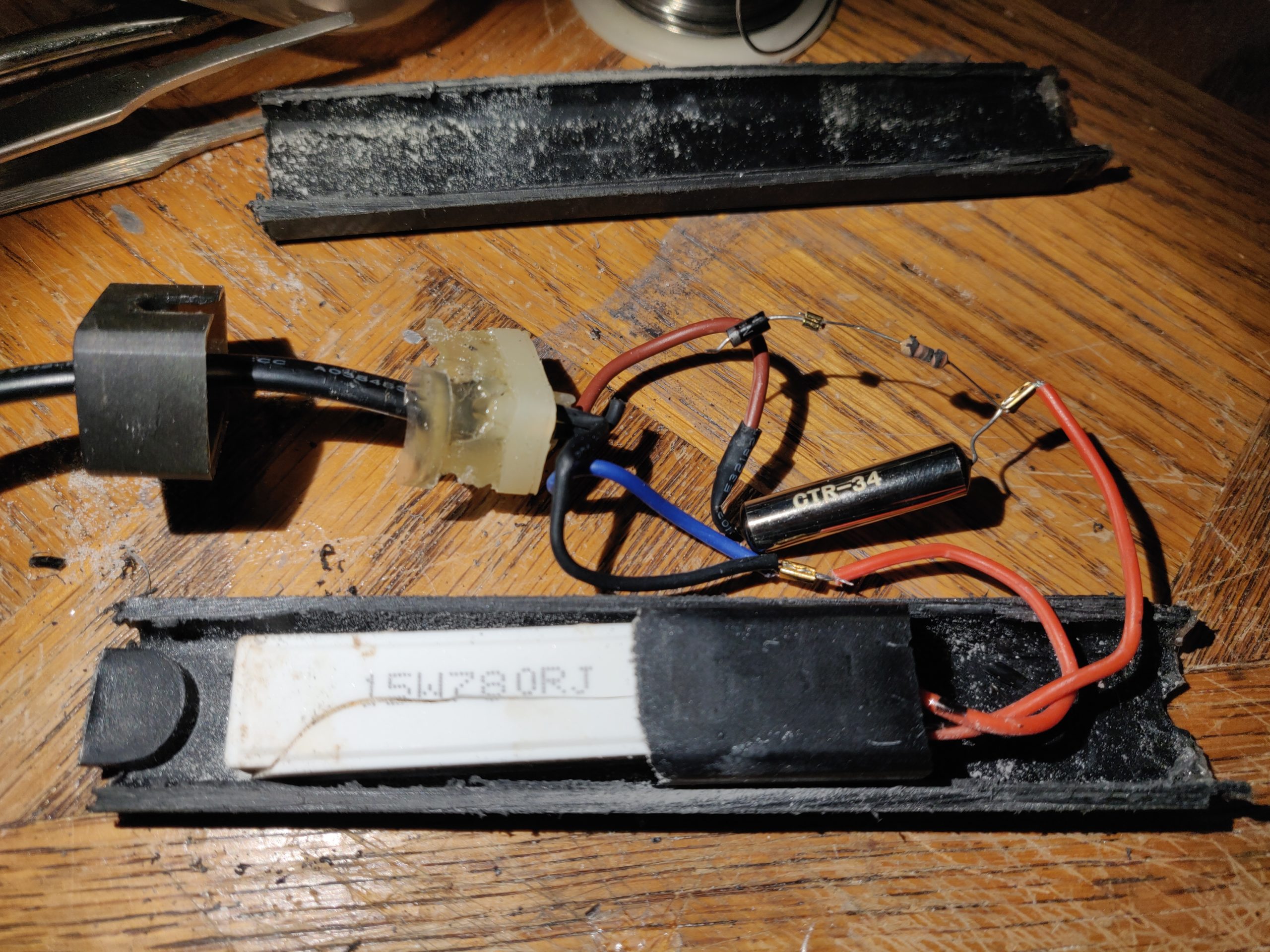

Tim Tears It Apart: SunGrow Betta Heater, a Sketchy Preset Aquarium Heater

Spoiler alert time. Did you know there are ferrous metal composites with arbitrary Curie points, extending down to room temperature and even below freezing? You never know where a teardown of a theoretically boring product will lead. Seriously, take more stuff apart, it’s good for you. I’ll spare you the lengthy story of the goldfish…

-

Other Utricularia for aquascaping besides UG

Utricularia graminifolia (UG) is a popular foreground plant for planted aquariums, with grass-like leaves that eventually form a lush green carpet over the substrate. It is considered anywhere between easy and impossible to grow, and has some special needs that make it not a beginner’s plant. However, there are a whole range of Utricularia that…

-

Disable automatic reboots on Windows 10 (maybe)

Look, I get it, updates are important, and so is installing them timely. But after waking up this morning to find yet-another overnight job lost to an automatic reboot, it’s the last straw. To afford nice things (you know, like computers), I need to do my job, and that requires actually using my computer and…

-

Notes To Myself: Fixing File Sharing in Windows 10 after “Fall Creators Update” breaks it

About 2 years ago, sharing movies from my desktop (Windows 10, alas) to the old Linux Mint laptop acting as a Chromecast-that-plays-local-content-without-weird-workarounds randomly stopped working, with Gigolo reporting the very helpful error, “Connection timed out”. Fair enough, it’s not Gigolo’s job to diagnose problems caused by dodgy Windows updates. After more Googling than it should…

-

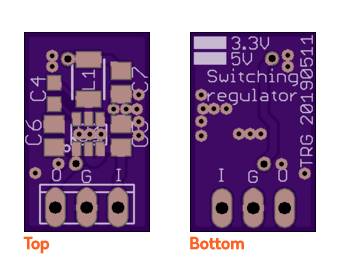

Silly Subproject: Switching 7805 / 7833 TO-220 replacement

Thanks to an oopsie on a larger project that involved not doing the math before dropping a small 3.3V linear regulator into a >20V input circuit design, I had a need to swap it for something that generated less finger-burning, board-cooking, smoky-smelling heat. I’m sure everyone and their dog has done one of these already,…

-

Not Dead

I’ve just been busy with a couple of little things. Now that the littlest one is figuring out this whole sleep thing, I might have time for projects again :-)