Asbestos undergarments? Check.

Lawyer-proof socks? Check.

Here we go.

I got a small safety lesson over the weekend I wanted to share. Officially, it’s about an extremely common design of wire-rack shelving units, but the real safety lesson is to double-check the workmanship of load-bearing products with a critical eye, because the manufacturer may not have!

Here, a simple cheap design choice combines with lax quality control inspection to produce a potentially unsafe product. The TL;DR is that insufficient and off-center welds are used as a primary load-bearing element on the Home Depot shelf design indicated below, allowing the shelves to fail in a way that dumps the contents (for the product described below, up to 350lbs, ~160kg, per shelf) off the shelf, and potentially onto the person who just put them there.

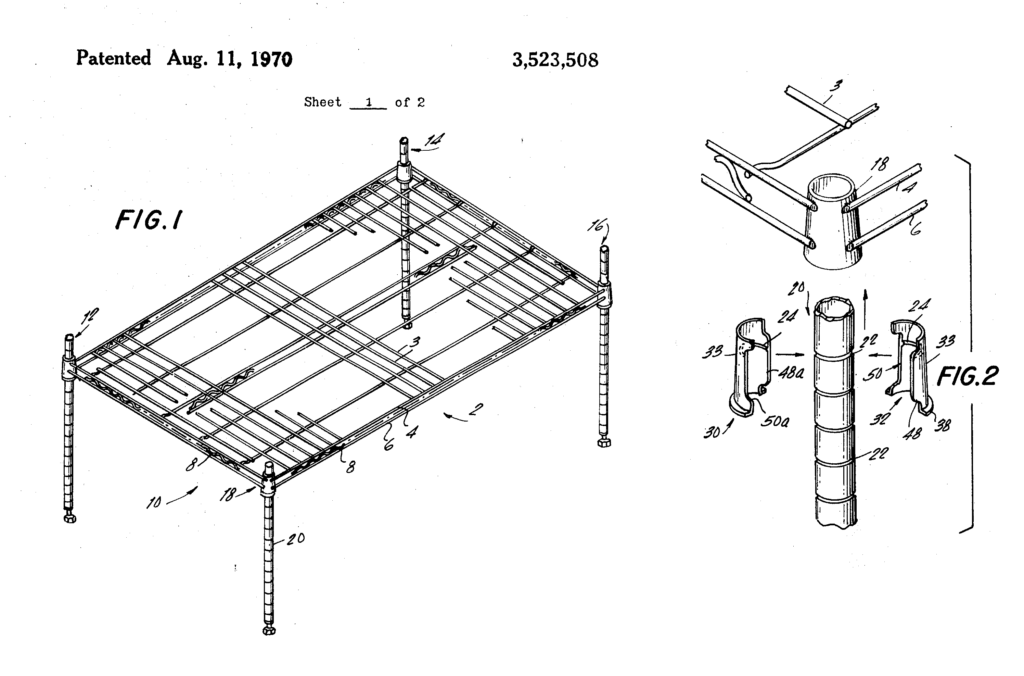

The basic wire shelving unit design I’m referring to dates back to at least 1970 and can be seen in US patent 3,523,508. While the one I purchased, depicted below, came from The Home Depot, you can buy a substantially similar product from most big-box retailers. They consist of a set of typically 3-5 rectangular wire-rack shelves that slip over a set of four corner support poles with grooves at intervals. Each shelf has tubular metal sleeves in the corners to receive the poles, and assembly consists of snapping a set of plastic rings (clamshell or mating half-rings) onto the poles at the groove corresponding to the desired shelf height, then sliding the shelf down the poles until it snugs in against the plastic rings. The plastic rings and/or the matching corner sleeves in the shelf are very slightly tapered, causing the shelf to wedge firmly into place and support heavy loads without sliding down. If you remember your grade school science class, a wedge is a classic simple machine, in this case converting the downward force of objects on the shelf into an outward force at the support sleeves, at a substantial mechanical advantage. With the narrow wedge angle and small size of these sleeves, the forces they must bear are significant to say the least.

The product photos below show the “HDX 5-Tier Wire Garage Storage Shelving Unit in Black (36 in. W x 72 in. H x 16 in. D)”, model # 21656PS-1, although as of this writing the website shows dozens of nearly identical products with various names and model numbers, differing in color or number of shelves (or not at all). This unit claims a load capacity of 350lbs (~160kg) per shelf, or 1,750lbs total. While setting the first shelf with a healthy downward hand-shove in each corner, I heard a small ‘tink’ sound as welds on one of the corner sleeves gave way. With these welds popped, slight hand pressure is enough to peel the corner sleeve open and send the corner of the shelf floorward (the plastic ring should not be visible above the sleeve at all).

The first obvious thing to notice on the Home Depot version is that the load-bearing sleeves are not continuous tubes of metal as shown in the original patent, but were rolled from sheet stock and have a seam. The small pair of welds serves double duty of fixing the wire shelving to the corner sleeve and holding the sleeve closed at the seam. Kind of a penny-pinching design choice, but it’s probably OK as long as those welds are solid…

The first set of broken welds, suffered before the shelf was fully assembled (let alone loaded) prompted a quick visual inspection of the other seam welds. In the photo below, the individual shelves are stacked alongside one another to show the variability in weld quality and placement. Holy wow!

The leftmost sleeve, now marked with red tape, is the same one that’s shown peeling open in the previous photo above, but without the force of the plastic ring it springs back to its original shape and the break is nearly impossible to see. The next, marked with yellow tape, is not yet broken (no attempt was made to assemble it), but the welds are so far off the mark that there is almost no material bridging the seam at all. This one is a disaster waiting to happen. Finally, the rightmost sleeves show more trustworthy welds, centered on the seam with adequate coverage on both sides serving to hold the sleeve closed. Ironically, each sleeve is pre-stamped with an NSF certification logo.

As previously mentioned, a lot is riding on these tiny welds: they bear the entire shelf load (or technically, 1/4 of it per sleeve, assuming the weight is perfectly distributed) via the outward force exerted on the sleeve by the wedging action of the plastic support rings. A failed seam weld will cause the shelf to tilt as that corner slides freely down its supporting rod, putting all the force as well as an unexpected bending moment on the remaining corners and, whether or not this results in a cascading failure, likely tipping the shelf contents onto the floor. Or, since this is most likely to happen in dynamic loading conditions, possibly onto whoever just placed the heavy thing there.

Hoping this unit was a fluke, I tried to exchange it for another of the same model. The employee working the returns counter brought out another and even invited an inspection before taking it home. Unfortunately, while the quality of the welds on the new unit wasn’t quite as bad as the first, there were still corners were only one of the welds traversed both sides of the seam at all. I left with a refund but otherwise empty-handed, apart from the associate manager’s business card and a promise to “run it up the chain”. We’ll see.

If you, dear reader, have a shelving unit like this already in use, I urge you to inspect it for the combination of seams at the shelf corner sleeves and shoddy welds holding them together. While welds are in general nontrivial to assess visually, even by experienced professionals, the process-control issues shown above are pretty obvious to inspection. That said, don’t ask me for advice on whether yours are “good” or “good enough” for “good enough to hold exactly 3 bags of concrete mix if set down gently”. Luckily, if in doubt, 1/2″ height pipe clamps will juuust fit between the typical shelf wires and could be used to bolster the corner sleeves – either as a permanent bit of due-diligence bodgework, or at least long enough to safely unload the unit if you’re not taking any chances.

DISCLAIMER: While the information above depicts a specific product, the underlying issue is not specific to one retailer or model number, and may occur on any unit with a similar design. This post and all statements it contains represents my personal opinion. It does not represent the opinions of my employer, my cat, The Home Depot, or any recognized safety agency. I am not an engineer (well, I am, but not a mechanical engineer), and this is not engineering, legal or any other sort of advice.

Leave a Reply